Wood oiling buffing polishing machine Double Buffer

Paoloni Double buffer flat oiling line units is suitable to spread perfectly colored hardwaxes after reverse roller coater applications for a perfect finished wood flooring. That specifical machine of Paoloni Floor coating solutions is the best surface treatment system to add on your wood flat industrial line.

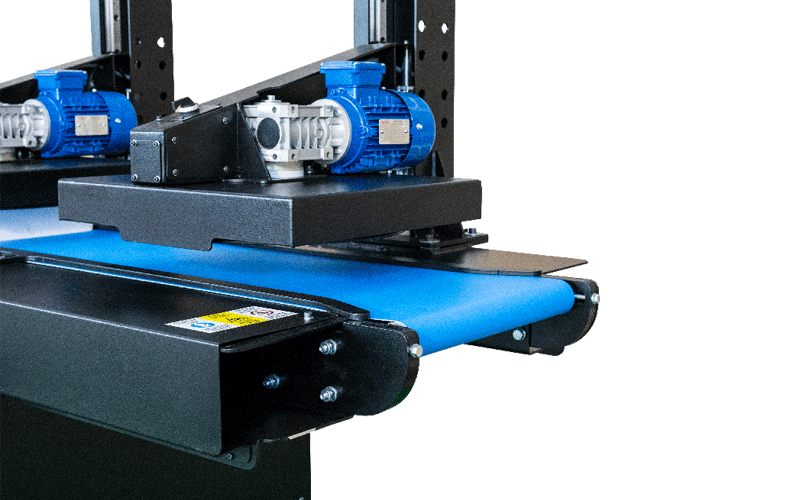

The Double Buffer is a machine designed to support two scotch-brite orbital pads with adjustable speed, a quick magnetic hooking system and felt replacement of the pad.

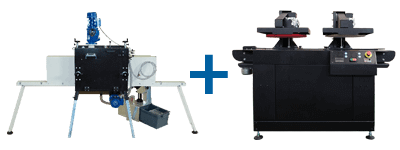

This machine is thought as a crucial unit of an industrial pre-finishing line. It has to be inserted immediately after a Roller Coater or a Minitunnel applicator, but only in case of use of high viscosity oils and hardwax products.

In many cases this polishing stage is has to be done between the application of the product and brush prefinishing (Double Wiper) This machine is thought as a crucial unit of an industrial pre-finishing line. It has to be inserted immediately after a Roller Coater or a Minitunnel applicator, but only in case of use of high viscosity oils and hardwax products.

In many cases this polishing stage is has to be done between the application of the product and brush prefinishing (Double Wiper) to let the oil to saturate and penetrate into every grain and irregularity of the wood surface, especially if it is handscraped or wire brushed. It is important to know that brushes and pads never cannot remove excesses, but they can only spread oil at best; the secret of a good application is about the first fundamental module that is the Minitunnel or a roller coater.

Any mistake in the setup of these machines will not be solved by the machines at the end of the line, for this reason Paoloni provides its customers with the opportunity to have specific and detailed training through their courses. It is possible to create a complete line that, as the last module, features ultimate LED drying lamps or classic UV lamps to dry specific products in real time. This is something that is now proposed by the major wood floor coating brands all over the world.

MINITUNNEL AND WIPING/BUFFING UNIT IN OILING LINE

INNOVATIVE PAOLONI CIRCULAR OILING LINE: BIG PRODUCTION ON SMALL SPACE

PAOLONI BUFING MACHINE AT WORK IN U.S.A. CUSTOMER FACTORY

BESPOKE TIMBER OILING FLOORING WITH PAOLONI FLOOR FINISHING MACHINES

Data Sheet

Dimensions and weight of the machine

- Length: 150 cm

- Width: 105 cm

- Height: 140 cm

- Total weight: 360 kg

Worktable tables dimensions

- Min. Thickness 5mm - max. 40 mm

- Min. Width 20 - max. 400 mm

- Min. Length 300 mm - max. NO LIMIT

Single-phase power supply:

- Nominal voltage: 220 V (50 Hz) (adaptable to any international standard)

- Total power 1,1 kW

Conveyor belt motor

- Power supply 220 V (50 Hz) (adaptable to any international standard)

- Power 0,37 kW

PAD motors with inverter

- Power supply 220 V (50 Hz) (adaptable to any international standard)

- Power 0,8 kW

- Adjustable speed: min. 10 RPM - max. 150 RPM

Production speed

- Meters/minute: 1 - 19

Electroactuated pneumatic lifting system of the brush with digital indicator

PAD diameter: 430 mm