Floor oil finishing machine Minitunnel 320

Minitunnel is a smart floor and timber finishing machine abble to work as oil roller coater and finish floorboards with any kind of solvent base stains and water based lacquers. Minitunnel electric and automatic machine is also suitable as lye and ageing wood product to give your wood a distressed and old effect.

The first and unique system that performs a vertical pre-finishing.

WHY PAINTING AND OILING WITH A VERTICAL FINISHING SYSTEM?

MACHINE FOR OIL AND HARDWAX APPLICATION ON SOLID OAK WOOD FLOOR

Minitunnel is the beating heart of the professional and flexible wood floor pre-finishing system thought by Paoloni Onelio & Figlio back in 2006. More than 400 Minitunnel laboratories have been sold in over 90 countries around the world so far and we are very proud to be the first company that use its own creation to produce and sell beautiful bespoke wood floors under the "Parquet Sartoriale" brand.

The Minitunnel basic module allows you to apply any kind of coating water-based and solvent-based pre-colours, 1 and 2 components finishes, straight oils and oils with waxes. With the a proper attention and specific application rollers it is even possible to use the Minitunnel to apply those aging products that are highly request by the market nowadays

The real innovation that everyone immediately notices is the vertical feeding system of the boards, which guarantees a great versatility as being able to be apply, in a single coat (with a production rate of up to 120 square meters per hour!), from 10 gr / mq up to 120 gr / mq without spilling on the groove and tongue and perfectly coating the bevels (micro or standard) on the 4 sides.

Minitunnel works well also with irregular surfaces such as handscraped or band-sawn boards. Thanks to the Minitunnel, Paoloni becomes a friend and partner of each of its customers. You can read what our customers from all over the world think about us. This makes us proud of offering a system that allows everybody to setup a successfull wood floor production, with higher incomes generated by the fact that all the products completely matches the customer desire.

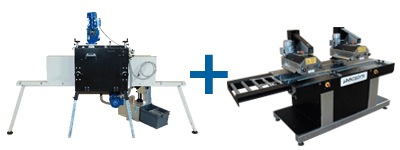

MINITUNNEL works at the best when paired with other machines such as a wire brush sander, a oil polishing line and buffing pads you can learn about on the other pages of this website.

MINITUNNEL AT WORK WHILE MAKING A PICKLED EFFECT OIL DOUBLE COLOR ON OAK FLOORING

MINITUNNEL AT WORK IN A FACTORY OF OUR CUSTOMER IN SOUTH AFRICA: THEY ARE FINISHING WITH HARD WAX OSMO (GERMANY) HARRING BONES AND CHEVRON PLANKS OF OAK

ONE OF OUR CUSTOMERS AT WORK WITH MINITUNNEL: APPLICATION OF A WHITE STAIN ON MAXI SIZE ENGINEREED LARCH PLANKS

ONE OF OUR CUSTOMER WHILE OILING WITH CHIMIVER LIOS BIOIL OLD WALNUT COLOR ON OAK FLOORING

MINITUNNEL AND RUSTICA THREE AT WORK REALIZING A SPECIAL CUSTOMIZED FLOOR IN OAK WITH BESPOKE FINISH STONE EFFECT

MACHINE EXPLANATION

SETTING AND USE

WOOD FLOOR OIL FINISHING SYSTEM ON SIDE

BESPOKE TIMBER OILING FLOORING WITH PAOLONI FLOOR FINISHING MACHINES

TOTAL TEFLON NO STICK TREATMENT

HAND MADE SCRAPED OAK FLOORING STAINING MACHINE MINITUNNEL WITH 2K LACQUER FINISH

PAOLONI WOOD FLOOR FINISHING SYSTEM

ONE MAN ALONE CAN MAKE A COMPLETE FINISHING PROCESS WITH OUR SYSTEM

HOW TO CLEEAN PROPERLY YOUR MINITUNNEL MACHINE IMMEDIATY AFTER WORKING SESSION (ASK YO YOUR OILS AND FINISHING PRODUCTS THE BEST CLEANER TO USE)

Data Sheet

Dimensions and weight of the machine

- Length: 210 cm

- Width: 62 cm

- Height: 180 cm

- Total weight: 235 kg

Worktable size

- Thickness min. 10mm - max. 45 mm

- Min. Width 30 - max. 320 mm (including tapping)

- Min. Length 600 - max. NO LIMIT

Single-phase power supply:

- Nominal voltage: 230V AC (50 Hz) o 110/120V AC (60 Hz)

- Total power 1,46 kW

Drive rollers motor

- 230V AC power supply (50 Hz)

- Power 0,55 kW

Finishing brush motor with speed gearbox

- 230V AC power supply (50 Hz)

- Power 0,55 kW

- Adjustable speed: min. 40 RPM - max. 200 RPM

- Brush pressure adjustment: +/- 15 mm

Electric pump

- 230V AC power supply (50 Hz)

- Power 0,34 kW

- (optional pneumatic pump upon request)

Production speed*

- Meters/minute: 14

- * (inverter for speed adjustment upon request)

Removable product basin

- N. liters 5L (small basin) - 20L (large basin)

HOW TO CLEAN MINITUNNEL AFTER WORK

HOW TO MAKE THE SETTING OF MINITUNNEL

Use and maintenance of the Minitunnel machine

How to apply oils with the Minitunnel

How to apply water-based stains with the Minitunnel

How to apply reactive stains with the Minitunnel

How to apply water-based lacquers with the Minitunnel

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

_1.png)

_1.png)

_1.png)

_1.png)

_1.png)

_2.png)

_2.png)

_2.png)

_2.png)