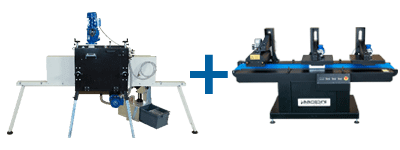

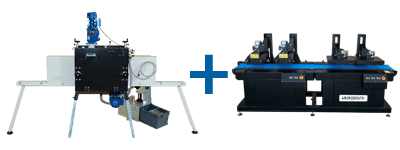

The Double-Wiper machine put in line with the MINITUNNEL allows a homogeneous spreading and a perfect buffing of full solid oils and pigmented hardwax oils. In the videos you can see how the Double Wiper (i.e. the two-head brushing machine) can be inserted in the queue of a flat standard roller coater (whose feed speed is limited for obvious reasons of functionality and cannot exceed 10 linear meters per minute), but PAOLONI guarantees full functionality also with the coating by the MINITUNNEL machine, twhich works up to 16 linear meters per minute of production capacity.

If we make a comparison between a flat Roller Coater and Minitunnel as the first application step of the wood floor prefinishing process, the Minitunnel guarantees almost double productivity compared to the flat line system, which so far has been universally recognized system as a standard. Moreover, the Minitunnel guarantees a greater versatility, a fast setup and cleaning, which is very important when you want to change the colour in use. Cleaning a Minitunnel requires between 10 and 20 minutes, while a roller coater requires one to two hours. You must consider everything when it comes to assemble you parquet laboratory and make all the calculation of production costs.

Last but not least, there is the possibility of placing a Double-Buffer between the Minitunnel module and the Double-Wiper line machine, or alternatively ask us to produce a two-head module, one of which is an orbital buffer while the second is a wiping brush for oil.

MINITUNNEL AT WORK IN LINE WITH BUFFING MACHINE

PAOLONI BUFING MACHINE AT WORK IN U.S.A. CUSTOMER FACTORY

BESPOKE TIMBER OILING FLOORING WITH PAOLONI FLOOR FINISHING MACHINES

Data sheet

Dimensions and weight of the machine

- Length: 150 cm

- Width: 105 cm

- Height: 140 cm

- Total weight: 360 kg

Worktable size

- Min. Thickness 5 mm - max. 40 mm

- Min. Width 20 mm - max. 400 mm

- Min. Length 300 mm - max. NO LIMIT

Single-phase power supply:

- Nominal voltage: 220 V (50 Hz) (adaptable to any international standard)

- Total power 1,1 kW

Conveyor belt motor

- Power supply 220 V (50 Hz) (adaptable to any international standard)

- Power 0,37 kW

Brushes motors with inverter

- Power supply 220 V (50 Hz) (adaptable to any international standard)

- Power 0,8 kW

- Adjustable speed: min. 10 RPM - max. 150 RPM

Production speed

- Meters/minute: 1 - 19

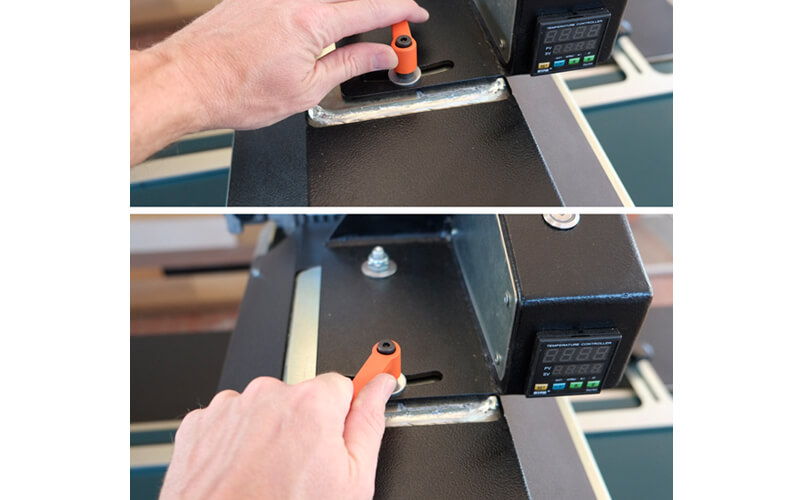

Electroactuated pneumatic lifting of the brush with digital indicator

Brush head inclinable +/- 35 ° with respect to the belt